新聞中心

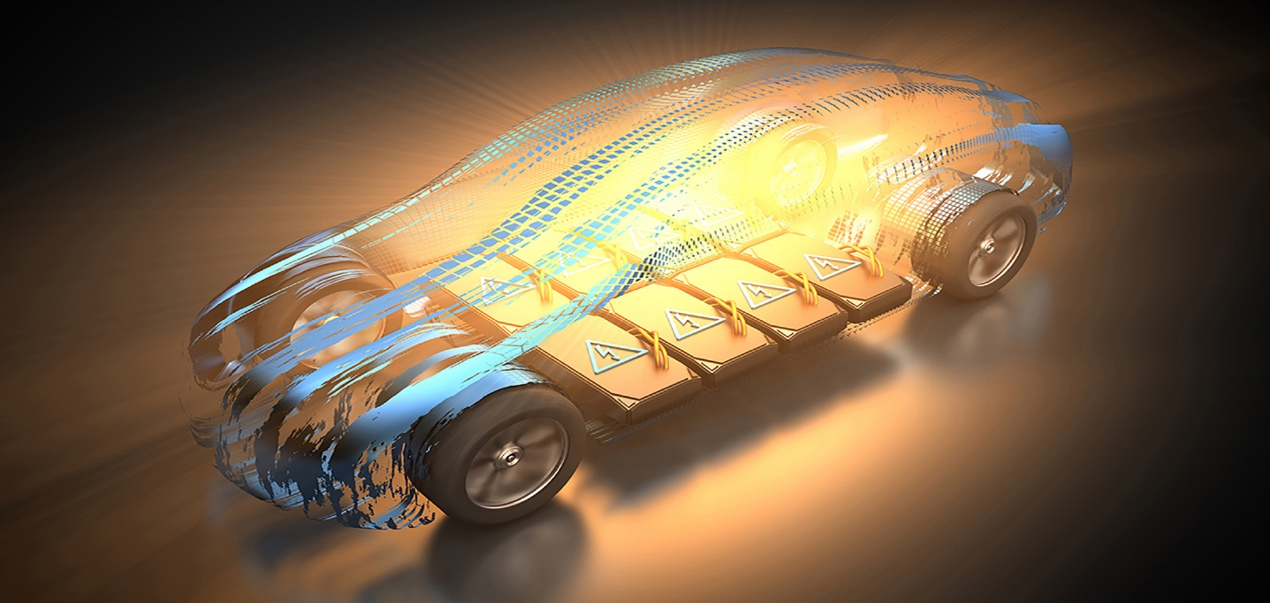

As the electric vehicle market rapidly evolves domestically, the pursuit of advanced heat pump systems is accelerating. GOUP Automation has dedicated itself to developing a series of highly intelligent and automated thermal management integrated module assembly testing lines.

This month, we successfully delivered a production line that includes liquid-side and agent-side assembly as well as multiple EOL (End-of-Line) testing stations, providing support for the rapid production of a high-end domestic vehicle model.

1.Data Management and Intelligence

The assembly testing line integrates an advanced production data management system, enabling real-time monitoring of the production process and equipment status. The intelligent management system enhances efficiency and transparency in production.

2. EOL Testing System

Our independently developed EOL (End-of-Line) testing system performs comprehensive performance verification of product attributes such as flow rate, pressure, and sensor status. This ensures that every thermal management module leaving the factory meets stringent quality standards.

3.Ergonomics

In designing the production line, we placed special emphasis on operator comfort and safety. Through thoughtful production line layout and human-machine interface design, we ensure that operators can work efficiently in a comfortable and safe environment.

1.Flexible Production Capability

The production line is designed with future product modifications and changes in production demands in mind, ensuring flexibility to accommodate the production of different specifications and types of thermal management modules.

2.Automation and Mechanical Design

The production line is equipped with automation devices tailored for thermal management modules, including assembly robots, handling systems, and testing equipment. The introduction of these automation devices significantly enhances production efficiency and product quality.

1.Automation Enhancement

We will continue to advance the automation of our production lines, utilizing robotic technology to achieve more precise component placement and assembly, further enhancing production efficiency and product quality.

2.Modular Design

Moving forward, we will adopt modular design concepts to make the production line more flexible and easily adjustable to meet the production needs of different products.

3.Integrated Testing System Optimization

We will optimize the integrated testing system to achieve higher levels of automated testing and quality control, ensuring that products meet all performance standards before leaving the factory.

4. MES System Enhancement

By integrating with order management and supply chain management systems, we will optimize production planning and scheduling, improving production efficiency and resource utilization. The future MES system will help us maintain a competitive edge in the market.

Smart manufacturing and automation are the future directions of the manufacturing industry. We will continue to drive technological innovation, constantly optimizing and enhancing our production lines to provide high-quality and efficient thermal management integrated module products to our customers. The successful acceptance of this thermal management integrated module assembly testing line is not only a significant achievement in our smart manufacturing efforts but also a steadfast commitment to creating greater value for our customers. Let us move forward together and embrace the promising future of smart manufacturing!